If you have some good product idea, but don’t know what to do with it, or who will design or develop it, then you are on the right site!

Services

- Consultations

- UX & UI Design

- Software development

- 3D Modeling

- Electrical Engineering

- Sales Material Compiling

- Prototype Development

- Small Scale Production

Portfolio

Library book return locker

Concept

A concept for a self-service device to accept return books outside of a library. An analysis for the construction of the cabinet was made for the client, price queries were taken from various manufacturers and 3D renderings were made, which will help the client to participate in the public procurement with his product.

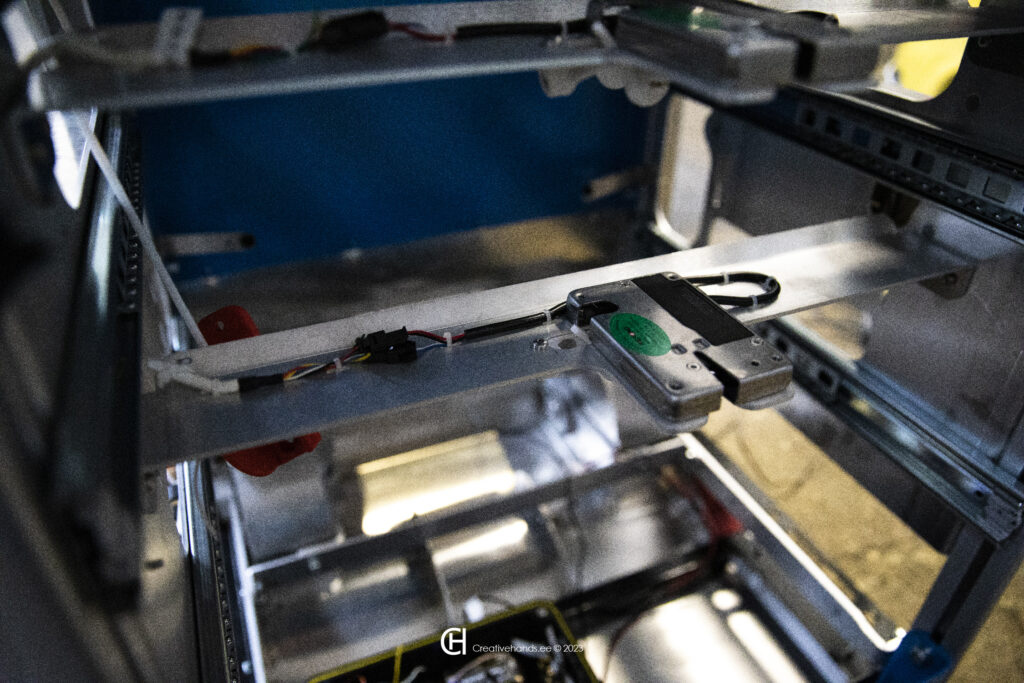

Intar MW Toolbox

The tool cabinet, secured with electronic locks, has GPS, LTE, LoRa networks for communication and tracking in case of theft, and Wi-Fi and Bluetooth connectivity to connect to a central server via the internet. Users who have access can be managed through the web administration, where you can also see log of who has opened the locker and where the locker is currently located and what its condition is.

Designed for clients who have theft problems

First designed for construction sites, where the tool cabinet can be wheeled on its own two wheels to where tools are needed. At the end of the working day, workers on a large construction site do not have to take the tools far away to a secure place, but can lock the tools in a mobile cabinet. The cabinet has a accelerator sensor, which detects tampering of the cabinet, during the off hours, and gives an alarm. Getting access to the main server over at least one of three networks, LTE, WiFi, LoRa, the device sends an alarm to the central database, where the security company and surveillance people are further informed.

Prototyping

The prototype of the device is created without knowing exactly what the customer might need in the end. All possibilities have been taken into account and space left for future features, such as:

- charging dock for tools with battery

- bigger or smaller drawer, up to 7 or more with addition board

- smaller or bigger drawers based on the need

- extension cord for receiving power from the mains

Web admin

In the online administration, it is possible to manage a fleet of toolboxes. You can see in real time where each cabinet is, what their current condition is, and manage employee access. The web admin is built so that the toolboxes can be rented or sold as a white label service, where the service provider and the end customer have their own access and views.

Monitor Wall

Story

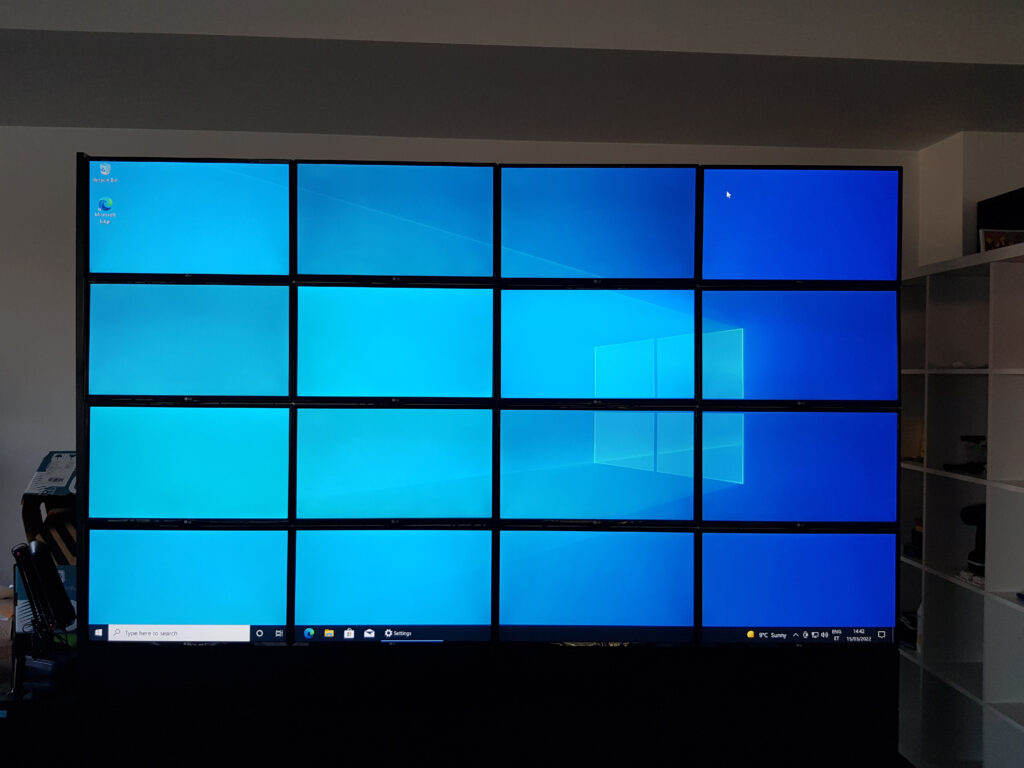

At the meeting, we discussed what to do with a large quantity of old FHD (1920x1080) monitors, which could not be used for anything and could not be thrown away. I proposed the idea of building a monitor wall and the idea was explored.

Research

First of all, it was necessary to figure out which device will play all the monitors. The video should be in sync and if possible run in FHD and 60Hz, i.e. the maximum that the monitor allows. We considered adding a Raspberry Pi computer to each monitor or two, or using four computers, each of which would run one.

When all options were examined, I found that with a budget of €1,000 you can purchase the necessary hardware (excluding existing monitors) and material to build the monitor wall. The HP Z820 workstation was chosen, in which four Nvidia NVS 510 cards, each with four DisplayPort slots, were installed. All the hardware was second hand, which was cheaper and gave the old hardware a second life. Also in terms of software simplicity, it was decided in favor of Nvidia cards, which would run in one platform so that Nvidia Mosaic technology could be used.

Design

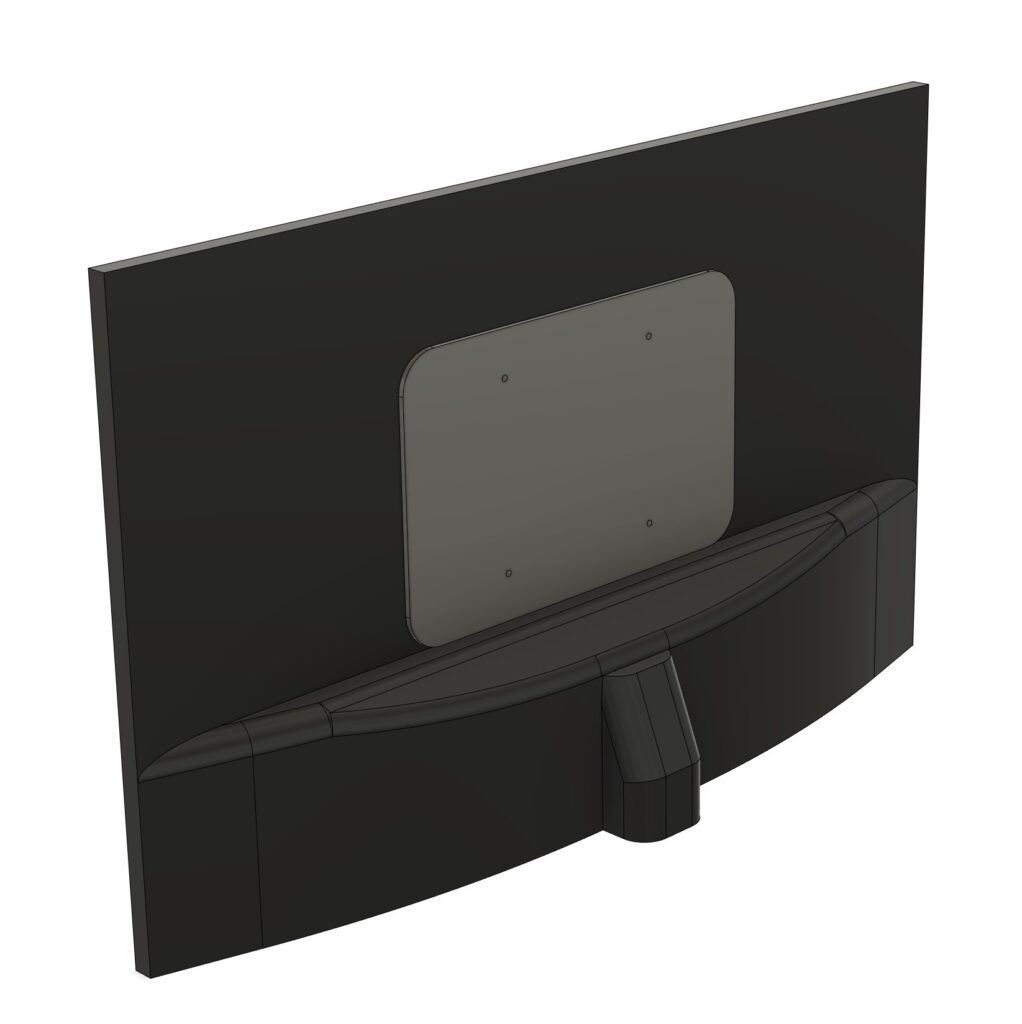

VESA

Since the monitors lacked VESA holes and no possibility of wall mounting at all, one solution was to permanently attach a metal plate compatible with the VESA100 standard to the back of the monitor with double-sided tape, with which it would be possible to mount the monitor to the monitor wall.

Since the monitors were also of different sizes, which would have made the screen wall very uneven, the final solution saw a wooden beam to which the monitor is attached thanks to another metal plate with four screws. This made it possible to position the monitors in two directions, left-right and up-down by 3~4cm. To move the monitor in and out, a block of different thickness was placed between the metal plate, which fixed the distance. The jaw and pitch of the monitor itself could be slightly changed by tightening screws in different corners.

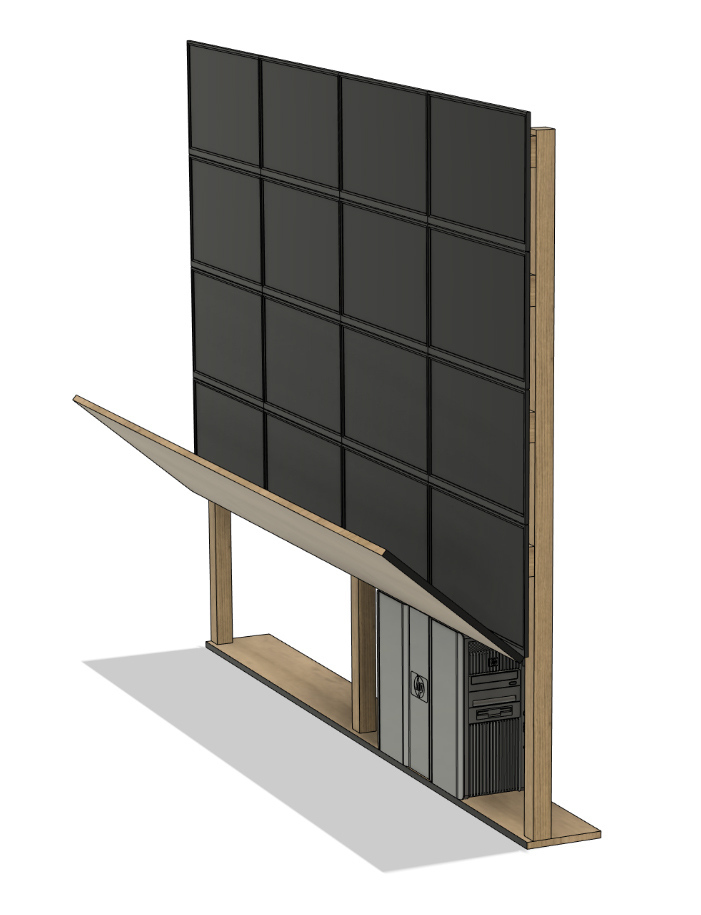

Monitor frame

The frame was made from wood to be lighter, cheaper and easier to construct. The lower hatch under the monitors is hinged and can be lifted, so that you can access the computer if necessary and make it more accessible when you need to pull the monitor away from the wall. The hatch was held in place by gas springs, which meant that the hatch did not have to be fixed when it was lifted.

Construction

The height of the monitor was 183cm, width 220cm and depth 22cm.

Finishing and calibration

Once the monitor wall was together, it was time to connect the cables and start setting up the Nvidia mosaic in Windows.

As a test, a video was run on the screens, which became Nyan Cat. As a result, you could see that all the screens were running in sync

The colors of the screens were also calibrated to be uniformly the same

Benchmark, multiple FHD videos can be run by one machine at the same time

Key word - giving new life to old technology.

The result - 8K 60Hz mosaic screen.

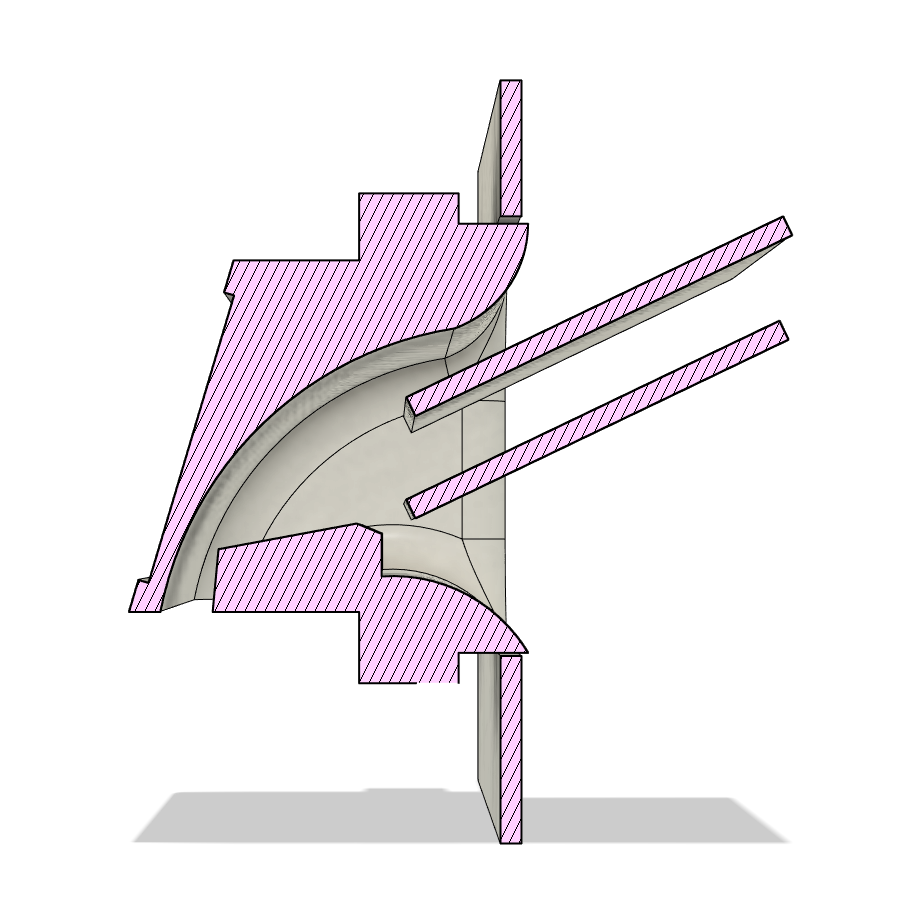

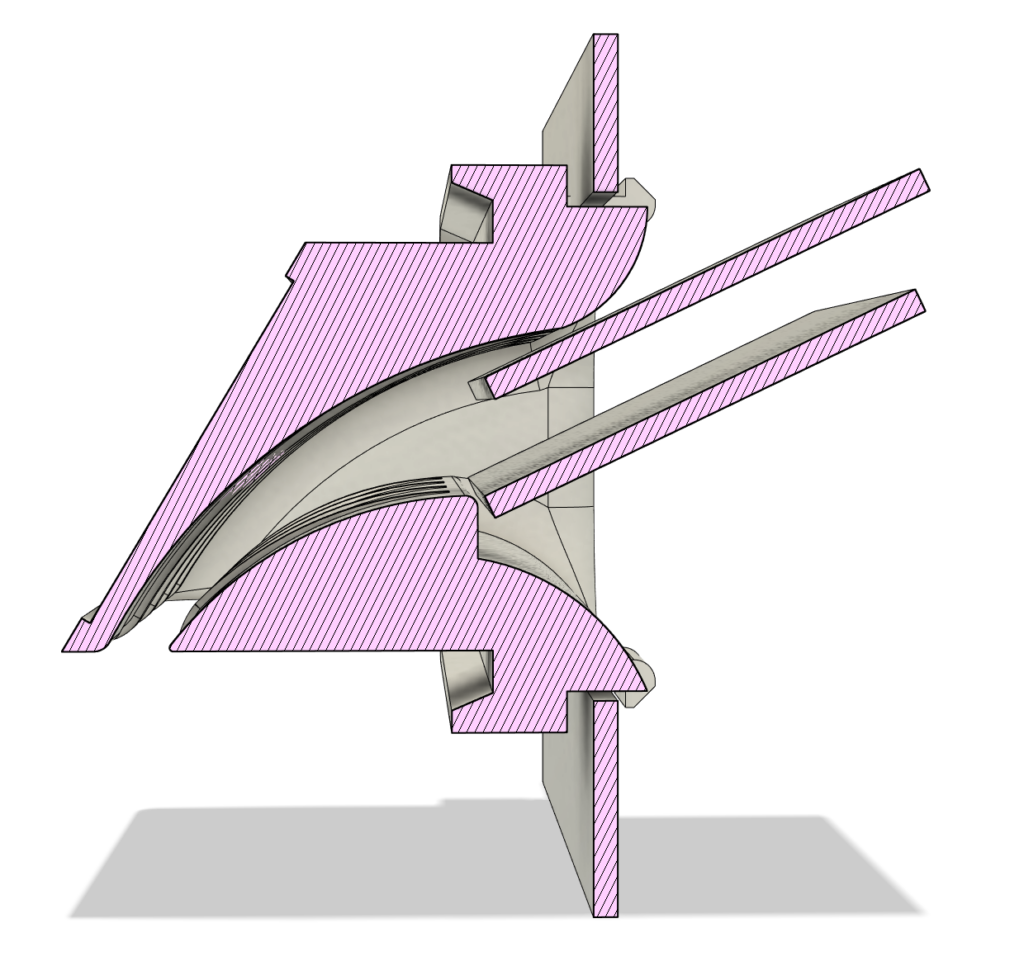

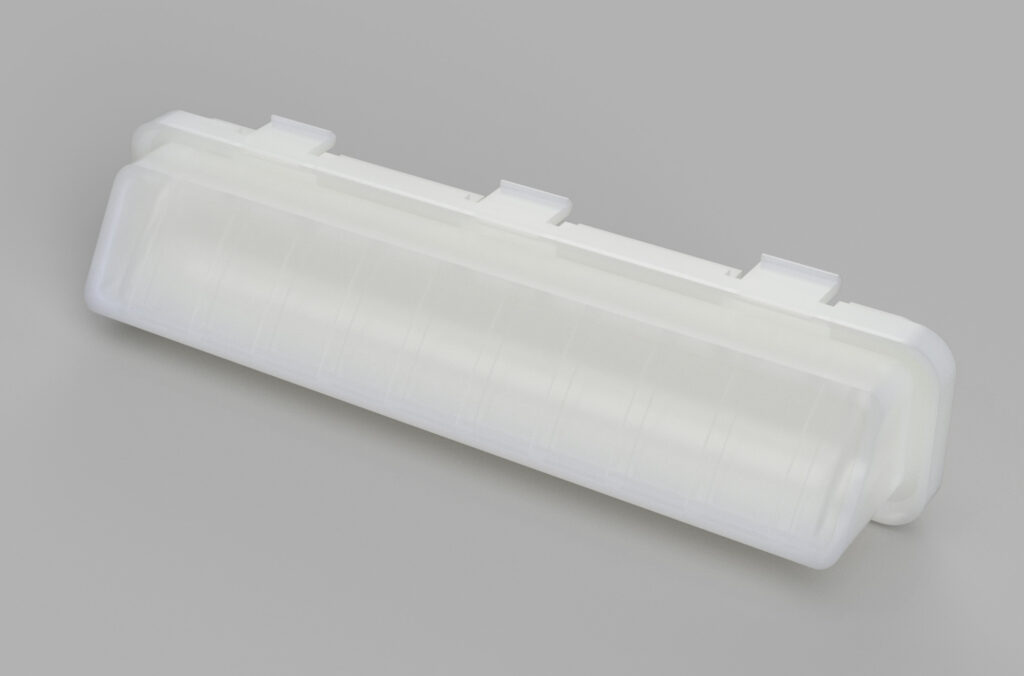

DPD parcel robot printer slot

The existing printer openings on DPD parcel robots, that direct the printed paper downwards, were originally designed poorly. The printed paper did not always come out and got stuck behind the inner edge causing jams. A new opening was designed based on the original model, where the exit transition was made smoother.

To improve the weather and UV resistance of the plastic part, the part was made of 3D-printed PETG material.

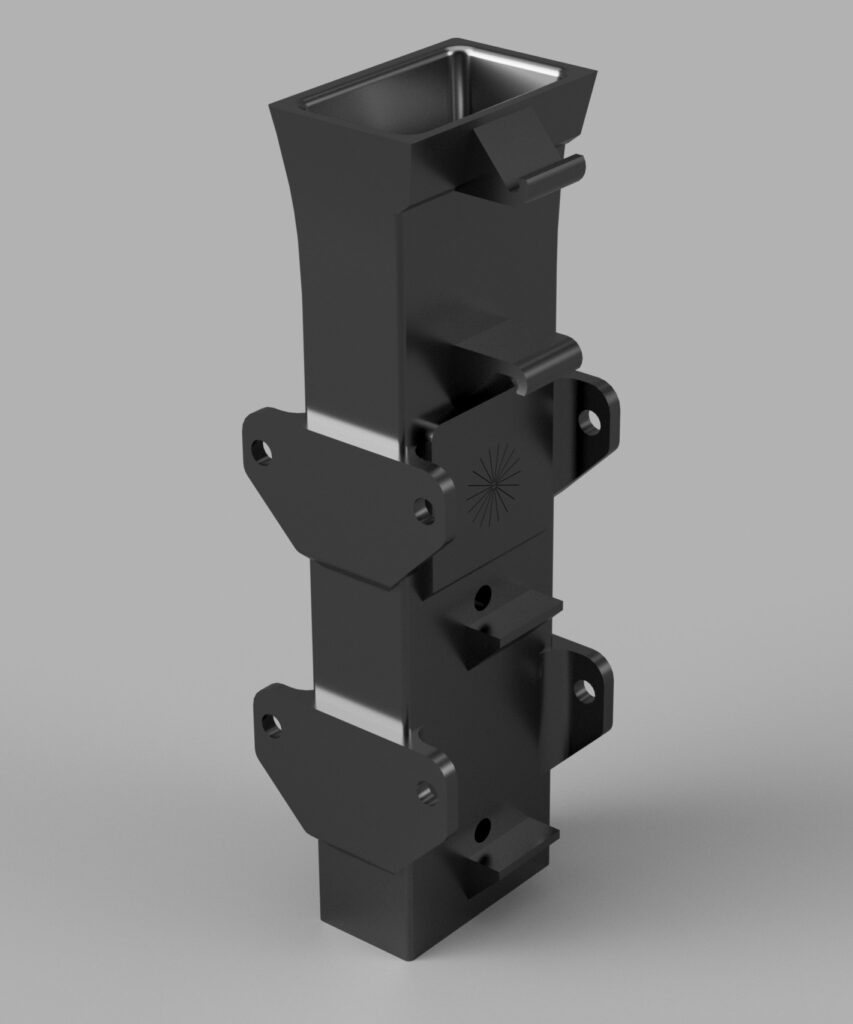

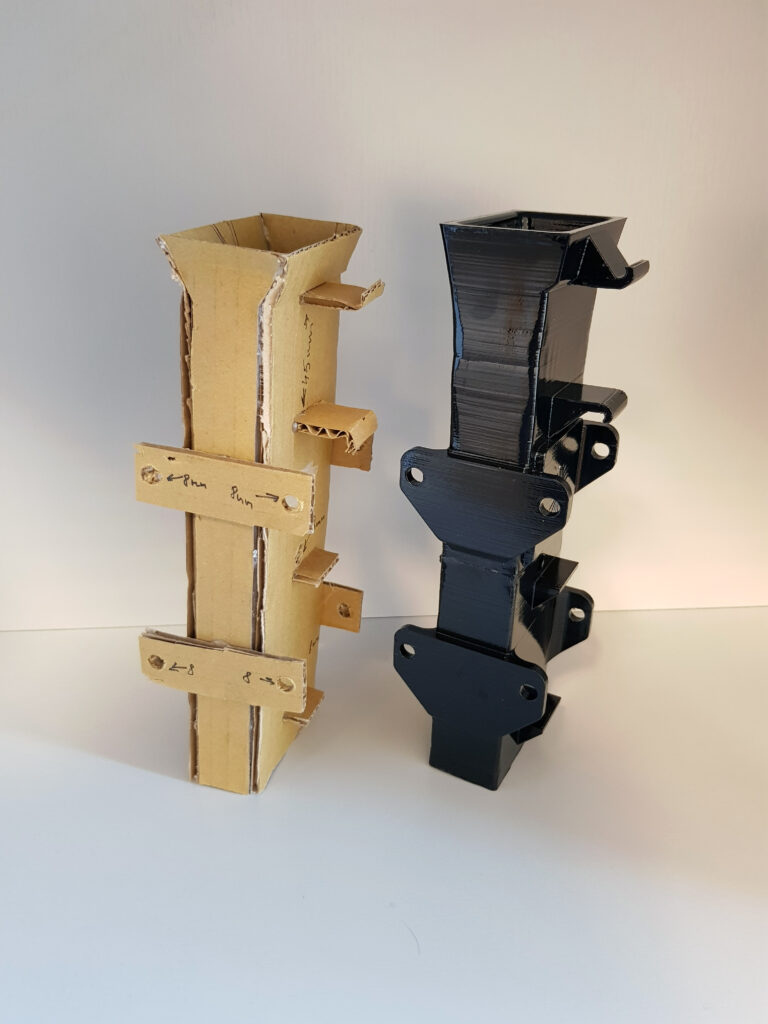

Security gate card reader

The client does not always have to have exact drawings or designs. Here is a good example where the customer, without using computer, simply made a cardboard model of the desired part. It has been jokingly said that CAD stands for Cardboard Assisted Design, which worked perfectly for this client. The client handed over a cardboard model and got a 3D model created and the final prototype part also 3D printed and finished.

Overall badges

It is the custom of Overall to have Christmas party for its employees every Christmas in the office, with different workshops. We made for one workshop LED-illuminated badges or reflectors that the workers could assembly themselves. Two types of badges were made, one with the Overall logo and the other with their mascot.

In terms of the simplicity, for easier assembly, of the electrical circuit, RGB LEDs were chosen, which require only 3V current and their own internal circuit changes the LED colors over time. In addition, it was possible to choose the LED shades you like. The scheme was kept simple with a battery, lights and a switch that disconnects the mains.

Based on the shape, different layers were chosen for the printed circuit board, and PCB production techniques were used to bring out various details. In addition, a gold finish was selected, i.e. the signs had a golden accent in the logo.

Button pendant housing

Wireless buttons are used in express checkouts in grocery stores, with which store workers can confirm the buyer's age, in case they are purchasing an age-restricted product. Since the button is small and tended to get lost or there was nowhere to attach it, so a pendant was designed and by only using 3D printing was produced. The case locks when the parts are bent and can be easily opened. The final product was 3D printed and processed in a small quantity.

NoBananas tasting trays

Unique and durable tasting trays were designed and created for NoBananas berry counters found in grocery stores and shopping centers, which would make everything easy and clear for the visitor. There is a place for clean toothpicks and a place to throw used toothpicks. The concept was designed around plexiglass thermoforming and the cups were 3D printed. When the created 3D model of the final product was confirmed, the tooling for the designed thermoforming came next and we produced the tasting bases for all NoBananas counters. The bases have lasted 5+ years so far.

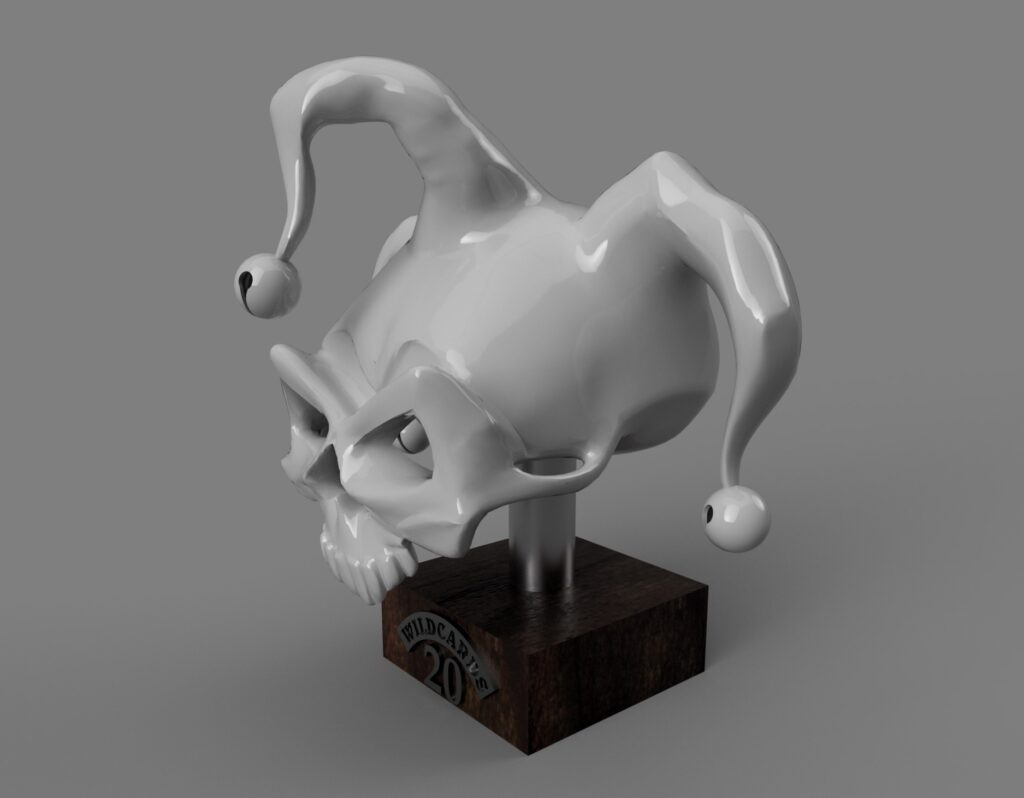

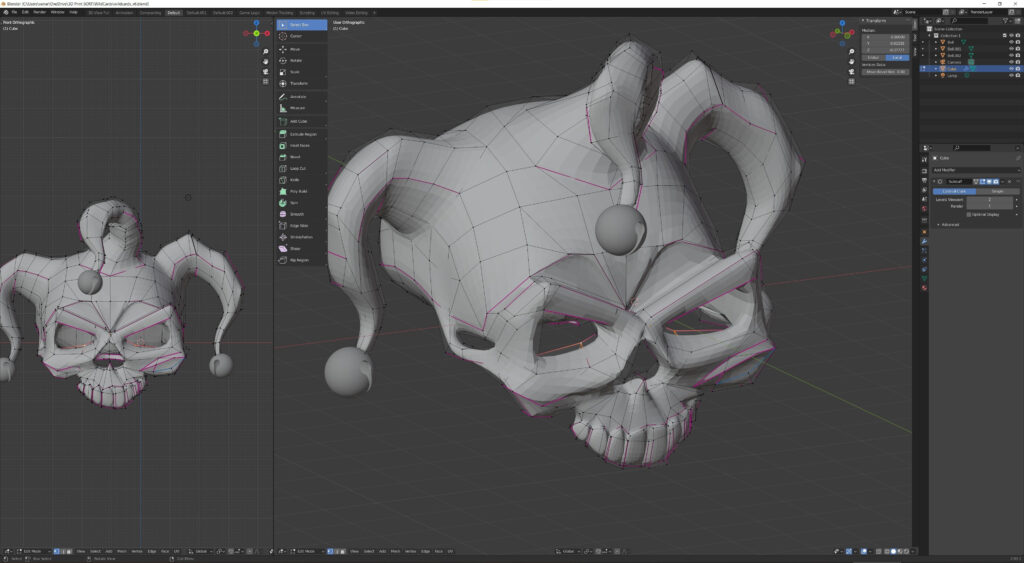

Tallinna Lennujaam trophy

For the 80th anniversary of Tallinn Airport, their partner MagneticMRO, ordered a trophy for them. The trophy was designed according to the new logo of Tallinn Airport, giving the 2D logo a 3d space and a wooden block chosen for the bottom. The text was transferred to the cup through toner transfer.

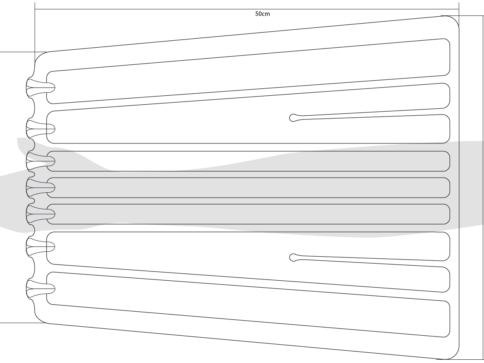

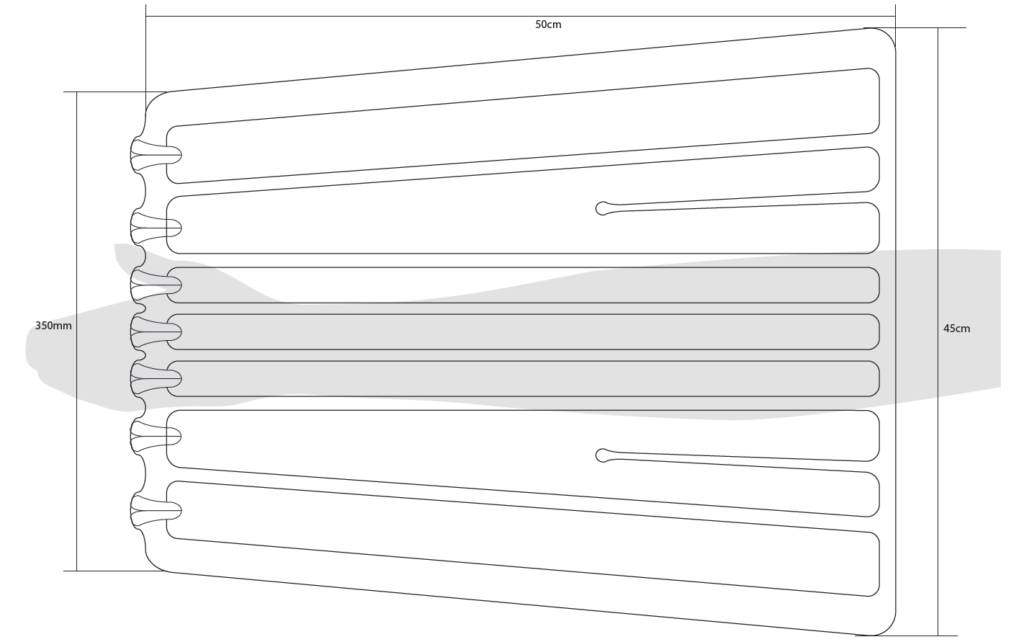

Airsplint arm splint prototype

A plastic and inflatable hand splint designed for military and rescue operations, which is very affordable, compact and quick to deploy. The splint consists of two films that are fused together at the edges and contain channels that are filled with air. The air is under pressure, which compresses the film valve from the inside and closes the valve as soon as the air filling nozzle is pulled out. The splint will hold the arm in a temporarily fixed position so that the broken bone does not move until the injured person is transported to the hospital. A brainstorm was carried out with the client on what the final product could look like and a rough sketch was designed.

If you are interested and wish to continue, contact us and get your first feedback.